Storage Tanks

| |

- Chemical Tanks

- Water Tanks

- large tank farms projects

- Fire fighting tanks

- Under ground tanks

- Special Design Tanks

- Rectangular tanks

|

- Propane tanks

- lube tanks

- fire resistance tanks

- double layer tanks

- waste water tanks

- floating tanks

- pressurized tanks.

|

|

|

| |

Manufacturing Activity: Includes: Design, supply of materials, manufacturing and Installation

- Carbon Steel Tanks: ASTM A234 WpB~WpC: WPHY-52,60,46,65 and 70

ASTM A420 WPL9,3 and 6

- Alloy: ASTM A2234 WP1,11,12,22,5,9 and 91

- Stainless Steel: ANSI, ISO, JIS, DIN, BS, and GB

- Volumes in cubic meters: 100 to 12,000

Contracting Activity: Includes: Site preparation, civil works, in-place welding, erection, paint-finishing, test and commissioning.

- Electromechanical automation

- Special coating

- Heating applications (High viscous materials like asphalt) / special pumping.

|

|

|

| |

|

|

|

| |

Tanks Farm Projects Design

Design works of miscellaneous steel and metal works for Tank Appurtenances,

Platform, Walkway, Stairway, Rolling ladder, Wind grinder, Drain Nozzle and Drain

Sump, etc. Welding all lugs, brackets and supports and any other miscellaneous

steel and metal works for tank appurtenances.

Also, the civil design starting from the land leveling, foundation design and concrete base design.

- Detailed Engineering:

P & I

Plot Plan ( arrangement)

Civil

Mechanical

Electrical

Instruments

Workshop drawings

- As build drawings |

|

|

| |

|

|

|

| |

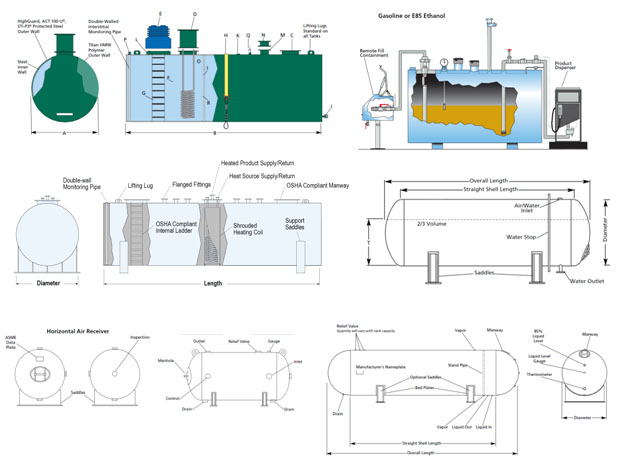

Major Types of Tanks

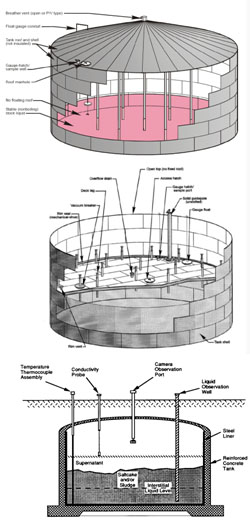

A. Circular Tanks

1. Above Ground liquid storage Tanks with fixed roof: made of welded or bolted steel sheet bended according to the engineering design, could be shipped to the site pre fabricated but it will need welding and finishing on site, there are different types of finishes like normal painting, epoxy, PE coatings, special coating depends on the specifications required and the materials used to be stored in the tank.

2. Above Ground liquid storage Tanks with movable roof or membrane : almost the same of the above tank but this tank will have special horizontal membrane that moves up and down to allow vapors and gases to expand or to restrict the vaporization of liquids by sizing the tank up to the stored materials surface .

3. Underground tanks: same as above but will be laid underground to store hazardous materials or to protect the tanks for accident or direct sun or fire, such tanks will require special venting openings and special outer lining or coating to be rust – corrosion resistance.

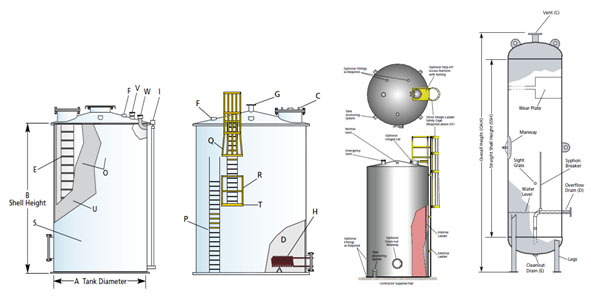

4. Above Ground vertical tanks: tanks with higher heights ration compared to its diameter, to build more pressure or to preserve construction space, below are some design samples; Our Company could fabricate any required shape according to approved drawings. |

|

|

| |

|

| |

|

|

|

|

| |

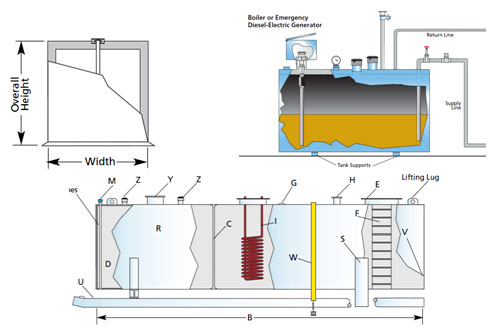

B. Rectangular Tanks:

used in petrochemical plants oil fields and other processing plants as receiving tanks, lubricant storage or sewage collection and could be above ground, underground or even elevated. |

| |

|

|

|

|

| |

|

| |

|

|

|

|

| |

C. Cylindrical horizontal Tanks:

used widely in petrochemical plants, factories, processing plants, storage or even mobile transportation over trailers or trains. Could be manufactured for liquids or liquefied gases (LG) such as LPG, Chlorine, CO2, O2 and other industrial gases, designed as underground, above ground or even elevated. |

| |

|

|

|

|

| |

|

|

| |

|

|